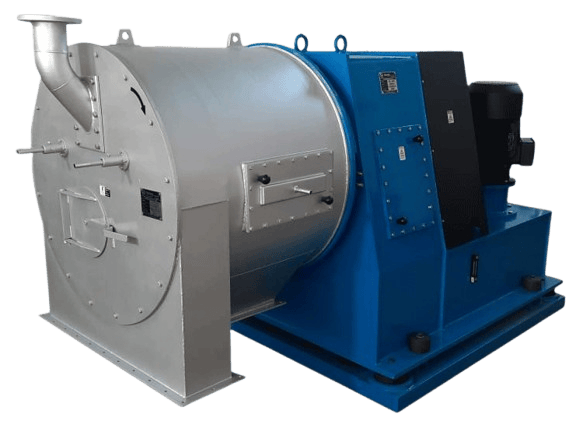

Hydraulic Pusher Centrifuge

Hydraulic Pusher Centrifuge Manufacturer

Shreeji Engineers are a trusted Hydraulic Pusher Centrifuge manufacturer in Ahmedabad, delivering reliable and continuous solid–liquid separation solutions for demanding industrial applications. Our Hydraulic Pusher Centrifuges are engineered to perform consistently under high-load and continuous processing conditions, ensuring stable cake discharge, smooth operation, and uniform throughput. With a strong focus on process reliability and mechanical durability, our centrifuge systems are designed to support uninterrupted plant operations and long service life.With successful installations across India, Turkey, Bangladesh, Philippines, Thailand, Sri Lanka, Tanzania, Uganda, and Indonesia, Egypt , Iran , Ghana our Hydraulic Pusher Centrifuge machines are recognized for dependable performance and robust construction. These systems are widely used in the Chemical, Salt, Fertilizer, Pharmaceutical, Food Processing, and Mineral industries, where efficient and continuous solid–liquid separation is critical for maintaining production efficiency and consistent product quality.

Working Principle of the Machine

A Hydraulic Pusher Centrifuge Machine operates on a continuous filtration concept. Slurry is fed into a rotating basket fitted with a precision-engineered screen. Under centrifugal force, liquid passes through the screen while solids are retained, forming a uniform cake layer.

A hydraulic piston applies controlled reciprocating strokes that gradually push the cake toward the discharge end. This hydraulic action allows continuous solid removal without interrupting feed, ensuring steady processing and uniform product quality.

Hydraulic Drive & System Design

The performance of a Hydraulic Drive Pusher Centrifuge depends largely on the accuracy and stability of its hydraulic system. Stroke length and pushing frequency are precisely controlled to match the filtration characteristics of the processed material.

A well-designed Hydraulic System for Centrifuge minimizes shock loads, reduces vibration, and ensures smooth cake movement even at high operating speeds. This controlled motion also helps preserve particle integrity and reduces mechanical wear over time.

Precision Engineering & Robust Construction

These machines are developed as Precision Hydraulic Centrifuge systems, where basket geometry, screen selection, and hydraulic actuation are carefully balanced. This precision ensures consistent cake thickness, effective liquid separation, and low residual moisture.

The rugged structure and reinforced components classify the equipment as a Heavy Duty Hydraulic Centrifuge, capable of handling continuous operation in harsh industrial conditions such as chemical processing plants and mineral handling units.

Industrial Applications & Use Cases

A Hydraulic Pusher Centrifuge is commonly used across multiple industries where continuous solid-liquid separation is critical:

- Chemical and specialty chemical processing

- Fertilizer and mineral production

- Salt and crystalline material processing

- Polymer and resin manufacturing

In particular, a Hydraulic Centrifuge for Chemical applications is valued for its corrosion-resistant construction and stable performance under aggressive processing environments.

Manufacturer & Supplier Capabilities

As an experienced Hydraulic Pusher Centrifuge Manufacturer, the emphasis is placed on application-specific design, material compatibility, and long-term operational reliability. Each system is engineered to suit the client’s process requirements, operating conditions, and production targets.

We also operate as a dependable Hydraulic Pusher Centrifuge Supplier, supporting clients with installation guidance, technical assistance, and spare part availability. Many industrial buyers prefer working with a supplier who is easily accessible when searching for a hydraulic centrifuge near me, ensuring faster service response and minimal downtime.

Design Optimization & Industrial Reliability

A well-optimized Hydraulic Pusher Centrifuge Design ensures the right balance between centrifugal force, hydraulic pressure, and filtration area. Proper system design leads to efficient separation, reduced energy consumption, and stable performance over extended operating cycles.

For operations requiring enhanced separation force, configurations such as a High Pressure Hydraulic Centrifuge can be developed to meet higher throughput and moisture control requirements.

Indian Industrial Conditions & Long-Term Value

An Industrial Hydraulic Centrifuge India must perform reliably under variable feed conditions, high ambient temperatures, and continuous duty cycles. These machines are built to meet such operational challenges while maintaining efficiency and ease of maintenance.

When evaluating investment decisions, factors such as energy efficiency, service life, and maintenance intervals often outweigh initial Hydraulic Pusher Centrifuge Price considerations, making long-term value a key selection criterion.

For industries seeking dependable continuous separation solutions supported by manufacturing expertise and responsive supply support, hydraulic pusher-based centrifuge systems remain a proven and effective choice.

Hydraulic Drive

Powerful hydraulic system ensures uniform pushing action.

Continuous Operation

Designed for uninterrupted industrial production cycles.

Low Vibration

Balanced construction provides smooth and stable running.

High Capacity

Handles large material volumes with consistent performance.

Low Maintenance

Robust design minimizes downtime and service cost.

Low Residual Moisture

Ensures drier output and improved product quality.

| Model | Basket Dia (mm) | Hy. Motor HP | Rotor Motor HP | Weight (Kg) | Size (LxWxH m) | Capacity (NaCl Kg/Hr) |

|---|---|---|---|---|---|---|

| HT - 250 | 275 | 5 | 7.5 | 1700 | 1.9 x 1.2 x 1 | 2000 |

| HT - 350 | 375 | 7.5 | 10 | 2000 | 2 x 1.25 x 1.1 | 3000 |

| HT - 450 | 475 | 10 | 15 | 2500 | 2.4 x 1.3 x 1.4 | 6000 |

| HT - 550 | 575 | 15 | 25 | 2800 | 2.5 x 1.3 x 1.4 | 10000 |

| HT - 650 | 675 | 20 | 30 | 3000 | 2.6 x 1.4 x 1.5 | 13000 |

| HT - 750 | 755 | 25 | 40 | 4200 | 3 x 1.5 x 1.7 | 17000 |

| HT - 850 | 855 | 30 | 60 | 5200 | 3.2 x 1.5 x 1.8 | 25000 |

| HT - 950 | 955 | 40 | 60 | 6000 | 3.2 x 1.6 x 1.8 | 32000 |

| HT - 1050 | 1055 | 50 | 70 | 7000 | 3.5 x 1.6 x 1.9 | 40000 |

Request Your Hydraulic Pusher Centrifuge

Contact our engineering experts to design a Hydraulic Pusher Centrifuge tailored to your process requirements.